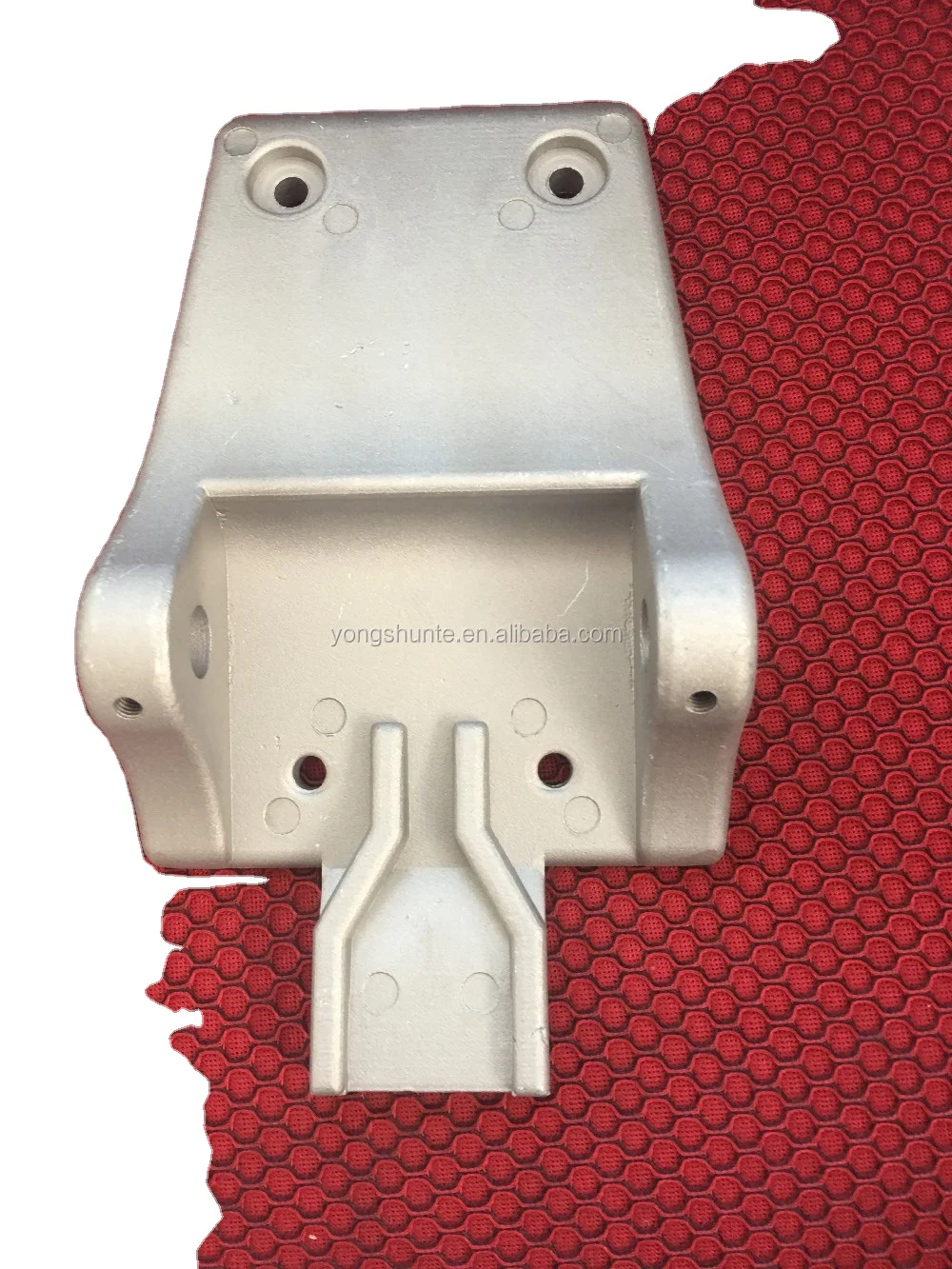

Precision aluminum casting solutions that improve product reliability and performance

Wiki Article

Discover the Important Advantages of Expert Shop Solutions for Your Manufacturing Needs

Professional foundry services supply significant benefits for makers seeking premium spreadings. These solutions integrate advanced innovation with skilled workmanship to achieve specific results. By outsourcing to expert foundries, companies can enhance cost efficiency and minimize production hold-ups. Additionally, the capacity to personalize and scale production offers engaging opportunities. As industries advance, comprehending these benefits comes to be significantly essential for preserving an one-upmanship. What various other variables should producers consider in this collaboration?Improved High Quality and Precision in Castings

In today's competitive manufacturing landscape, the need for enhanced quality and precision in castings has ended up being significantly crucial. Expert factory services play an essential duty in satisfying these demands by utilizing sophisticated technologies and competent workmanship. These services ensure the production of spreadings that not just satisfy yet frequently surpass market standards for dimensional accuracy and surface area finish.The integration of computer-aided style (CAD) and simulation techniques permits shops to enhance the casting procedure, minimizing defects such as porosity and imbalance. Moreover, the usage of top notch materials and strict high quality control measures further boosts the integrity and sturdiness of the end product.

Price Efficiency and Time Savings

While numerous producers look for to improve their functional performance, expert shop services offer a tactical benefit by substantially minimizing costs and saving time throughout the manufacturing process. By outsourcing spreading requires to specialized shops, firms can get rid of the expenditures associated with keeping in-house facilities and skilled labor. This approach reduces expenses and permits suppliers to assign sources better.Moreover, specialist foundry solutions improve the manufacturing timeline. With established workflows and progressed strategies, these solutions promote quicker turnaround times, making it possible for makers to fulfill tight deadlines and respond without delay to market needs. The decrease in manufacturing hold-ups not just reduces inventory expenses however additionally improves money circulation.

Inevitably, engaging with professional foundry services converts to a more reliable production procedure, where financial savings in both time and costs can remarkably boost a business's one-upmanship in the sector. This efficiency enables producers to concentrate on core service activities while ensuring top quality deliverables.

Accessibility to Advanced Innovation and Expertise

Accessing sophisticated technology and experience via specialist shop solutions significantly enhances a supplier's abilities. By leveraging state-of-the-art devices and innovative procedures, shops can generate high-grade elements that meet stringent market requirements. This access permits suppliers to gain from the latest advancements in products science, casting strategies, and quality assurance steps, ensuring that their items are not only affordable but also reliable.Furthermore, the competence of skilled engineers and service technicians within expert factories provides indispensable assistance throughout the manufacturing procedure. Their knowledge makes it possible for producers to identify potential issues early, enhancing styles and reducing the threat of flaws. This joint strategy fosters improved item performance and resilience.

In an ever-evolving market, the assimilation of sophisticated technology and specialized expertise settings suppliers to adapt promptly to altering needs, ultimately leading to improved productivity and growth. By utilizing expert foundry solutions, Precision aluminum casting manufacturers can ensure they remain at the leading edge of their industry.

Modification and Flexibility for Diverse Projects

Specialist factory solutions provide considerable customization and versatility, providing to a vast array of project demands. aluminum casting. By using advanced methods and modern technologies, these services can produce components customized to specific dimensions, materials, and aesthetic preferences. This versatility is vital for sectors that require distinct designs and specs, such as aerospace, automotive, and medical sectorsClients take advantage of the capacity to collaborate carefully with factory professionals, making certain that their unique needs are met throughout the production process. Whether it involves altering mold designs or adjusting alloy compositions, professional shops can suit numerous demands that boost the last product's performance and performance.

This degree of modification expands to small-batch manufacturings, allowing businesses to introduce without the constraints of standardization. Inevitably, professional shop services equip suppliers to realize their visions, supplying them with the versatility required for diverse and developing project needs.

Enhanced Production Scalability and Dependability

Exactly how can foundry services guarantee both scalability and integrity in production? Professional foundry services utilize sophisticated modern technologies and techniques that boost both elements. By making use of automated processes and maximized workflows, factories can adjust production quantities efficiently, guaranteeing they meet changing market needs.In addition, a dedication to quality assurance and extensive testing procedures develops a dependable result that clients can rely on. This dependability is essential for preserving long-term collaborations and conference strict due dates. The assimilation of data analytics also enables shops to prepare for manufacturing challenges and reduce threats proactively.

Inevitably, the mix of adaptive production techniques and strict top quality actions positions foundry services as a foundation for organizations looking for scalable and regular production remedies. Organizations leveraging these services can with confidence broaden their procedures, recognizing they have a trustworthy companion to support their development.

Regularly Asked Inquiries

What Products Can Be Utilized in Expert Foundry Services?

Professional foundry solutions make use of numerous products, consisting of aluminum, steel, iron, and bronze. These products are picked for their unique residential or commercial properties, suitability for specific applications, and ability to fulfill the diverse requirements of various manufacturing procedures.Just how Do I Select the Right Foundry Solution copyright?

Picking the ideal factory company includes evaluating their experience, top quality of materials, manufacturing abilities, and customer testimonials (Precision aluminum casting). In addition, evaluating their technical improvements and communication abilities can help ensure a successful collaboration for manufacturing jobs

What Is the Regular Preparation for Casting Projects?

Regular lead times for casting projects vary, usually ranging from a few weeks to a number of months. Variables influencing this include job intricacy, material availability, and the shop's work, needing mindful planning to meet target dates successfully.

Exist Environmental Regulations Affecting Foundry Workflow?

Yes, environmental guidelines greatly impact foundry operations. These policies attend to exhausts, waste monitoring, and source use, ensuring that foundries conform with sustainability methods while lessening their environmental impact and advertising accountable manufacturing processes.What Industries Frequently Make Use Of Specialist Shop Providers?

Several sectors make use of expert factory services, consisting of vehicle, aerospace, energy, and construction. These industries depend on shops for generating critical parts, making certain quality materials, and meeting specific production standards necessary for their operational success.Specialist factory services offer substantial benefits for producers seeking top quality castings. While several makers seek to boost their functional efficiency, specialist factory services give a critical advantage by significantly minimizing expenses and conserving time throughout the production procedure. Professional shop services streamline the manufacturing timeline (Precision aluminum casting). Ultimately, involving with professional factory solutions equates to an extra efficient production process, where financial savings in both time and costs can incredibly enhance a company's competitive edge in the sector. Accessing advanced innovation and competence via professional factory solutions substantially enhances a supplier's abilities

Report this wiki page